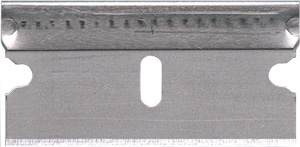

2-Facet: A good balance of sharpness and durability. Primarily for scraping and basic cutting.

3-Facet: Precision ground third angle increases sharpness. Used for thin or delicate material. Reduces foreign material transfer. Developed with specific cleanroom applications in mind.

Stainless Steel: Best for precise applications where corrosion can be an issue, such as cleanroom environments. Provides precise initial cut.

Carbon Steel: Durable for tougher and harder material. Best for scraping applications.

Plastic Blade: Best for applications where safety, scratches, pitting, and rust are a concern. Blades come in a variety of tensile strengths, have a longer lasting edge, low moisture and chemical absorption, a low friction coefficient, and a longer shelf life. Perfect for glass, plastics, chrome, marble, and painted surfaces.

Coated Blade: Improves lubricity through cutting process for cleanest cuts.

Uncoated Blade: No additional coating. In many cases coatings are not needed for application, and the blade tends to be less expensive than coated blades.

Degreased Blade: A cleaning process developed to reduce oil and particulates from manufacturing process to create the cleanest blade available.

Heavy Duty Blade: A .012" thick blade is considered heavy duty. With a thicker steel edge the blade can withstand super tough jobs whre regular duty blades will break.

Backing or Spine: Steel backing will create a stiff blade. Aluminum backing allows for blade flexibility. Stainless steel is best for environments where corrosion is a concern.

Still not sure what you need to get the job done? Contact Us and our friendly blade experts will be happy to help!